Target Markets

Target Industries

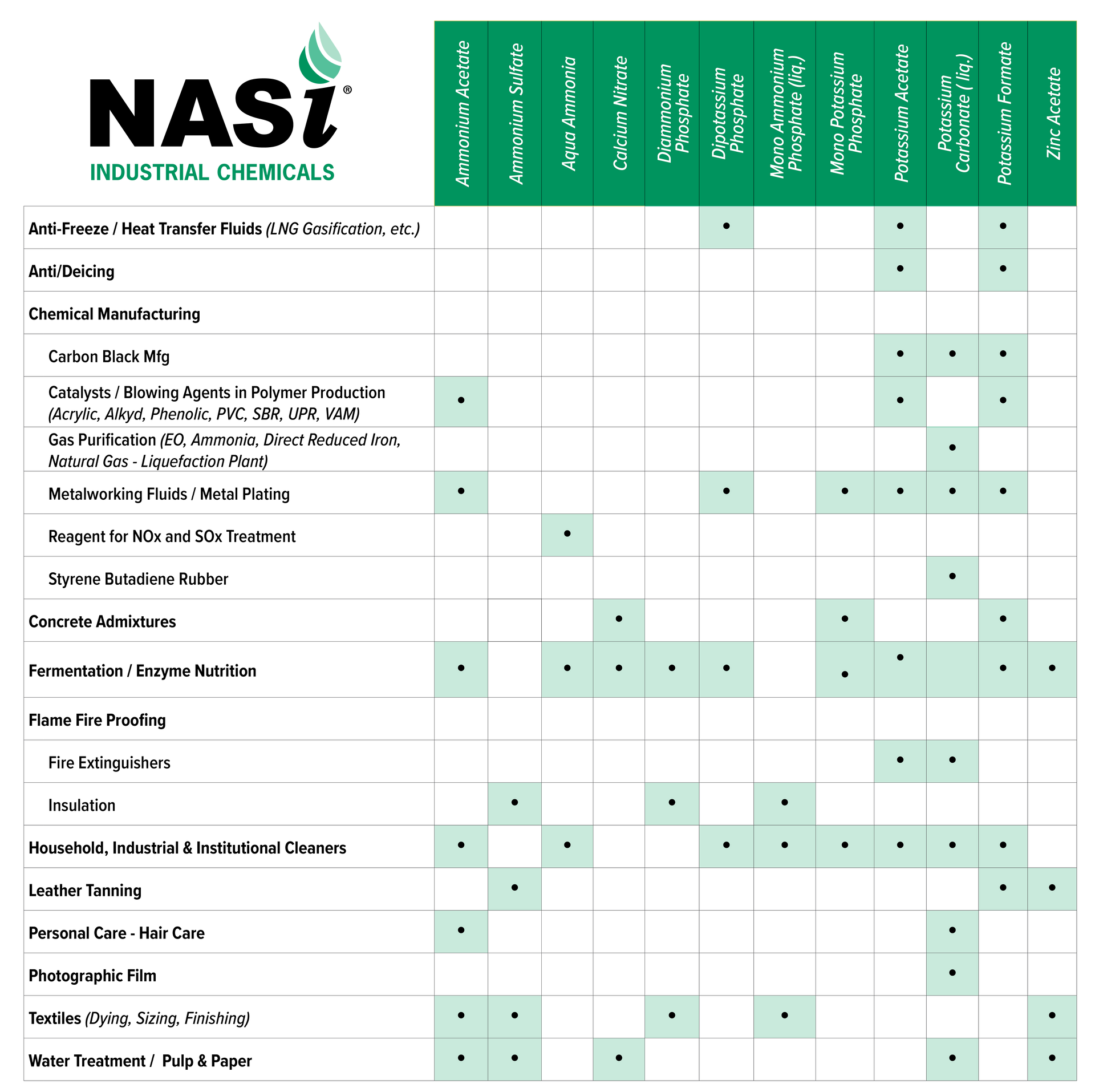

NASi manufactures liquid chemicals for various industries. Products are easily formulated to meet customer quality and industry regulations.

- Anti/Deicing

- Automotive

- Chemical Distribution

- Chemical Production/ Catalysts

- Detergents & Cleaners

- Dyes/Pigments

- Electronic/Circuit Boards

- Fermentation/ Nutrient Growth

- Flame/ Fire Proofing/ Extinguishing

- Gas Purification

- Glass/ Refractory

- HI&I Cleaners

- Land Reclamation

- Metal Chelate Micronutrients

- Metallurgy

- Metal Working Fluids

- Pavement/Concrete

- Plastics/Resins/Rubber

- Pollution Control

- Power Generation Scrubbers

- Pressure Testing

- Pulp/Paper

- Refrigeration

- Secondary Coolant

- Urethane Foams

- VAM Catalyst

- Water/Waste Water Treatment

Target Industries

- Anti/Deicing

- Automotive

- Chemical Distribution

- Chemical Production/ Catalysts

- Detergents & Cleaners

- Dyes/Pigments

- Electronic/Circuit Boards

- Fermentation/ Nutrient Growth

- Flame/ Fire Proofing/ Extinguishing

- Gas Purification

- Glass/ Refractory

- HI&I Cleaners

- Land Reclamation

- Metal Chelate Micronutrients

- Metallurgy

- Metal Working Fluids

- Pavement/Concrete

- Plastics/Resins/Rubber

- Pollution Control

- Power Generation Scrubbers

- Pressure Testing

- Pulp/Paper

- Refrigeration

- Secondary Coolant

- Urethane Foams

- VAM Catalyst

- Water/Waste Water Treatment

NASi manufactures liquid chemicals for various industries. Products are easily formulated to meet customer quality and industry regulations.